Types of Personal Protection Equipment (Clone)

Many industries, from health care to construction, require the use of personal protective equipment (PPE) to keep workers safe from job-related dangers. For example, a laboratory technician works with a range of potentially hazardous chemical, radioactive and biological substances. The Occupational Safety and Health Administration (OSHA) has regulations to reduce the risk of exposure to roughly 400 hazardous chemicals in a laboratory.

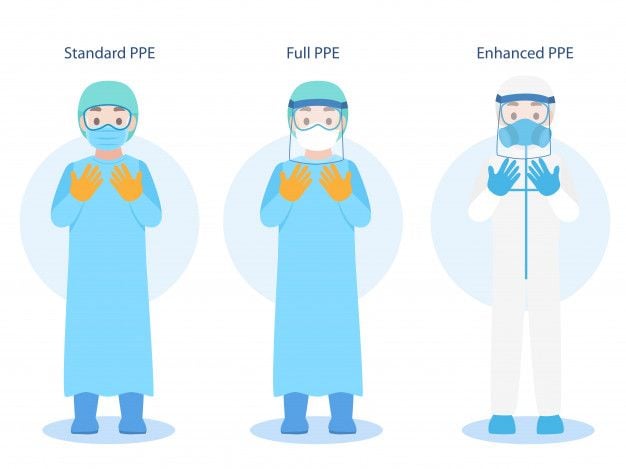

Although PPE cannot completely eliminate risks in any workplace, it can serve as a barrier between an employee's eyes, nose, mouth and skin and potential dangers to reduce the risk of illness or injury. For this reason, OSHA requires employers to provide their workers with PPE and ensure protective devices are used any time an employee handles a potential hazard.

To choose the appropriate PPE, employers must evaluate the workplace and the risks employees regularly face. If you are looking for the right PPE for your laboratory but aren't sure what you need, keep reading. We'll explore the different types of PPE and how each one provides protection.

What Is PPE?

PPE refers to the gear worn by someone to stay safe while working. PPE examples include protective safety goggles or glasses, face shields and disposable gloves. PPE must be selected to suit the specific job requirements and provided to the employees by the employer.

For example, if your laboratory handles blood samples, you need to comply with OSHA's Bloodborne Pathogens standard, which requires employers to pay for and provide the appropriate PPE for workers. In this case, PPE might include masks, gowns, gloves and goggles. OSHA suggests the following steps for selecting PPE:

- Identify and consider potential hazards.

- Determine the type of PPE available for the hazards you've identified.

- Consider the effectiveness of the PPE, and make your selection.

- Ensure you provide a variety of sizes to fit all employees properly and comfortably.

- Choose PPE that is compatible with other protective equipment you already own or plan to buy.

What Are the Different Biosafety Levels?

If you manage a biological laboratory where employees handle infectious agents, the minimum PPE includes a lab coat, safety glasses and protective gloves. Workers should also wear enclosed shoes and long pants. It helps to remember the different biosafety levels defined by the Centers for Disease Control and Prevention (CDC) when shopping for the appropriate PPE, which are:

- Biosafety level 1 (BSL-1): BSL-1 labs provide necessary PPE that is appropriate for handling agents not known to cause human disease in healthy adults. Nonpathogenic E. coli is an example of a microorganism that may be examined in a BSL-1 lab.

- Biosafety level 2 (BSL-2): BSL-2 labs provide PPE that is appropriate for handling agents that are known to cause human disease through ingestion, or percutaneous or mucous membrane exposure. Examples of microbes that may be found in a BSL-2 lab include the hepatitis B virus and salmonella. BSL-2 PPE should include gowns, gloves, goggles and face shields.

- Biosafety level 3 (BSL-3): BSL-3 labs require PPE that allows employees to handles agents known for potential aerosol transmission or which might cause serious infections. You might work with mycobacterium tuberculosis in a BSL-3 lab, for example. Along with PPE needed for BSL-2 labs, employees may also require respirators in a BSL-3 lab.

- Biosafety level 4 (BSL-4): BSL-4 labs require the highest level of protection and PPE that is appropriate for handling exotic, highly infectious and life-threatening agents with no known treatment. Ebola is an example of a microbe handled in a BSL-4 lab.

What Are the 4 Different Types of PPE?

For individuals working in a laboratory setting, there are four main categories of PPE which protect the face, respiratory system, hands and body from work-related hazards. Here's a look at each category and how they increase safety.

1. Eye and Face Personal Protection Equipment

OSHA requires employers to provide face and eye PPE if employees are exposed to hazards such as flying particles, infectious substances, gases, vapors or liquid chemicals. According to the CDC, about 2,000 workers a day experience an eye injury at work, and chemical burns are a common cause. Injuries can occur if a chemical enters the eye from around or under protective eye equipment, so it's essential to select the correct safety glasses or goggles for the job.

Ideally, eye and face PPE should fit properly, be somewhat comfortable and not impair a worker's vision. Eye and face PPE must comply with standard Z87.1-1989 or later, which was set by the American National Standards Institute (ANSI). Here are the types of face PPE to consider for your lab:

Safety Glasses

Protective safety glasses feature lightweight metal or plastic frames and durable lenses. Depending on the model, you might be able to select glasses with side shields. Safety glasses should feature polycarbonate lenses that offer impact-resistance, ultraviolet (UV) light protection and anti-fog capabilities. Since these glasses do not form a seal, they are only recommended for use in low-hazard settings and when handling substances that are not likely to cause eye damage.

Chemical Splash Goggles

Chemical splash goggles fit snugly on the face and form a seal around the eyes, eye sockets and surrounding areas. This creates a barrier against splashing or spraying chemicals and protects the wearer against impact. Splash goggles may feature indirect ventilation, which also prevents fogging.

Like safety glasses, goggles may be available with UV protection and scratch-resistant features. They may also be designed with removable or prescription lenses. Goggles can be appropriate for working with hazardous materials that may potentially splash.

Face Shields

Face shields consist of a transparent plastic sheet that stretches from the eyebrows to below the chin and completely across the width of the face. Face shields might be disposable and feature stretchable, cushioned headbands. This PPE device protects an employee's entire face from splashes, sprays and dust. They should be worn when lab workers handle materials that can damage the skin, such as liquid nitrogen.

Face shields should not be used as a replacement for respiratory masks in settings where aerosol hazards exist, and they are typically worn in addition to goggles or safety glasses. For example, if employees work with BSL-2 materials, they should wear a face shield in addition to safety glasses. If they handle cryogenic liquids, chemical splash goggles and a face shield may be appropriate.

2. Respiratory Personal Protection Equipment

Depending on the nature of the job, employees may need to wear mouth and nose or respiratory tract protection. According to the CDC, many common laboratory procedures could potentially produce aerosols and larger droplets, such as pipetting, sonicating, loading syringes and various other tasks. The type of respiratory PPE or mask needed depends on whether workers have to protect lab samples from themselves or shield themselves from infectious agents or chemical hazards.

As an employer, you may need to fit-test respirators for each employee to ensure they fit properly. For example, according to OSHA's Respiratory Protection standard, it is the employer's responsibility to fit-test tight-fitting respirators when such PPE is needed to protect workers' health. Here are face and respiratory PPE to consider:

Surgical Masks

Surgical masks are disposable, loose-fitting barriers designed to protect others and lab samples from the wearer's respiratory droplets. A surgical mask may be used when working with live animals and infectious materials in the BSL-2 category.

This type of PPE also helps prevent large particles from reaching the wearer's nose and mouth but does not filter very small particles or protect the wearer from breathing in gases or vapors. Surgical masks do not require a fit test.

N95 Respirators

N95 respirators protect the wearers from microorganisms, dust, fumes and mists. They are designed to fit snugly and efficiently filter out at least 95% of airborne particles greater than or equal to 0.3 microns. N95 respirators may be worn when conducting aerosol-producing tests or working with live animals, infectious agents in the BSL-2 category or dusty settings. N95 respirators require a fit test to ensure it forms a seal on the wearer's face.

Half-Mask Respirators

Half-mask respirators create a seal over the nose and under the chin and feature cartridges that purify the air the wearer breathes. You can choose the appropriate cartridge to filter specific contaminants and prevent the wearer from inhaling hazards such as dust, fumes and mist. Half-mask respirators are fairly lightweight and can be useful when working with infectious agents, live animals or chemical vapors.

Full-Face Respirators

Full-face respirators function similarly to half-mask respirators and purify the air depending on the cartridges used. However, full-face respirators cover the entire face and protect the eyes and surrounding facial areas in addition to the nose, mouth and chin from chemical splashes, vapors and mists.

This type of respirator may be ideal when workers need a high degree of respiratory protection and also want to shield their eyes and face. The downside is that full-face respirators are heavier than other types of respiratory PPE and are usually less comfortable to wear.

3. Hand Personal Protection Equipment

Protective gloves are made from a range of materials and are designed to protect the wearer's hands when they need to handle infectious agents or chemicals. It's important employees have access to gloves that were created for specific chemicals and conditions. OSHA's Hand Protection standard requires employers to provide hand PPE whenever workers are exposed to hazardous substances that can be absorbed by the skin or if they might experience burns or lacerations.

Be sure you select gloves that can resist the chemicals workers use without increasing the risk of ergonomic injury or loss of dexterity. Also, consider the type of contact workers have with chemicals, how long they work with hazards and if they require protection from abrasions. Keep in mind that gloves do not last forever, and need to be replaced periodically to provide optimal protection. Here are the different types of hand PPE commonly found in a laboratory or health care setting:

Disposable Gloves

Disposable gloves help prevent the spread of infection and may protect wearers from punctures. Due to their versatility, disposable gloves are appropriate for a variety of settings. Disposable gloves are typically available in small, medium or large sizes and should fit wearers comfortably but correctly. Be sure to choose gloves that also cover the wrists. Disposable gloves may be made of the following materials:

- Latex: Latex gloves may be powdered or unpowdered, and protect against biological hazards that fall under the BSL-1, BSL-2 and BSL-3 categories. It's important to consider that some employees may be allergic to latex.

- Nitrile: Nitrile gloves offer general resistance to chemicals, punctures and abrasions. Nitrile gloves can be worn to protect against splash hazards, but they should not be used when working with explosive materials or large volumes of solvents.

- Vinyl: Vinyl gloves provide the same level of protection as latex but are generally the more economical choice.

Chemical-Resistant Gloves

Chemical-resistant gloves are typically made with a rubber material such as butyl, nitrile, neoprene, fluorocarbon or latex. They might also consist of a plastic, such as polyvinyl chloride (PVC) or polyethylene. Typically, thicker gloves provide greater protection and also impact the ability to grip, so you'll need to consider the task.

Think about the type of chemicals employees encounter and what you need to protect them. According to OSHA, butyl gloves guard against substances like alcohols, peroxide and corrosive acids. Butyl gloves may be ideal for those who work with large volumes of toxic materials, whereas nitrile gloves are suitable for dexterity tasks.

Insulated Gloves

Insulated gloves guard the hands against extreme temperatures. Terrycloth autoclave gloves, for example, are heat-resistant and may be used for working with an open flame or hot liquids. Cryogenic gloves are water-resistant and protect against ultra-cold temperatures and cryogenic liquids.

Metal Mesh Gloves

If laboratory staff handle live animals, they may need metal mesh gloves. Metal mesh gloves protect the hands from cuts and scratches and are simultaneously flexible.

4. Body Personal Protection Equipment

Employees working with hazardous chemicals also need to protect their clothes and bodies from splashes and spills. The University of North Carolina at Chapel Hill recommends employees wear a lab coat any time they work in a biological, chemical or multi-purpose laboratory. Here are the different types of body PPE to consider:

Lab Coats

In general, lab coats protect the skin from hazardous spills or splashes and provide a removable barrier. As long as employees do not wear lab coats outside of the laboratory, they also help prevent the spread of contamination. Ideally, all lab coats should feature snap buttons for easy removal and fit employees properly. Types of lab coats include:

- Traditional: Traditional lab coats may be made of lightweight, breathable cotton or a polyester-cotton blend. Traditional lab coats protect the skin and clothing from dirt, dyes, radioactive substances and low-risk chemicals or biohazards. This type of lab coat is not suitable if fire hazards are present.

- Flame-resistant: Flame-resistant lab coats may consist of meta-aramid fiber. These coats may be appropriate in labs where workers handle flammable or potentially explosive chemicals.

- Barrier: Barrier lab coats are designed to keep infectious substances from passing through three layers of material. Cuffed sleeves allow the wearer to place gloves over the sleeves. Barrier lab coats may be ideal for working with blood, cells or tissues. Barrier lab coats may consist of polyester and should not be worn in settings with fire hazards.

Depending on the setting, lab employees may need to wear an apron over their lab coat to minimize their exposure to harmful substances. A lab apron might consist of vinyl, PVC or neoprene, and should be considered if employees handle acids, face thermal hazards or work with a high risk of chemical splashes. Ankle-length aprons offer adequate protection against heavy volumes of hazardous liquids.

Gowns

Like lab coats, gowns help protect the wearer from infectious materials and keep them from spreading contamination beyond the workplace. Exam gowns should feature long sleeves with elastic cuffs, an opening in the back, a close fit to the body and full coverage of an employee's lap while sitting.

Choose a gown that suits the setting and consider whether you want disposable or reusable gowns. The U.S. Food and Drug Administration classifies gowns by levels, with Level 1 providing minimal protection for low-risk situations and Level 4 providing high protection for dangerous conditions.

Although lab workers should wear closed-toe shoes, they might also need shoe covers, particularly if they work with pathogens or handle hazardous chemicals. Shoe covers help protect wearers from exposure to airborne pathogens and contaminated surfaces. They may be made of polyethylene or polypropylene to resist liquids. Lab workers might wear shoe covers when cleaning a chemical spill, for example, or to add a barrier when working with live animals. OSHA's Bloodborne Pathogens standard requires shoe covers when "gross contamination" is expected.

Head Caps

Heads caps are often made of polypropylene and available in a blue or white bouffant style. They are designed to protect an employee's hair and scalp from potentially hazardous fluids. Like shoe covers, head caps may be required PPE under the Bloodborne Pathogens standard, depending on the job and setting.

Hearing Protection

Depending on your lab, you may need to supply workers with hearing protection. For example, if lab employees work with sonicators, centrifuges or any other loud equipment, they'll need protection for their ears. Under OSHA's Noise standard, employees should not be exposed to noise levels over 85 decibels for an eight-hour shift. Common hearing protection devices include:

- Earplugs: Earplugs may be pre-molded or formable. Pre-molded earplugs are available in a range of shapes and sizes and do not expand. Formable earplugs expand within the ear canal to form a seal and can fit different sized ears.

- Ear muffs: Ears muffs cover the entire external ear and feature acoustic foam inside of each muff cup to decrease noise. Ear muffs are most effective when they form a tight seal on the head.

- Hearing bands: Hearing bands feature earplugs connected to a band that can be worn around the neck when not in use. Hearing bands typically cover the opening of the ear canal but do not create a seal. Therefore, hearing bands usually provide less protection than other devices.

When choosing hearing PPE for employees, consider how a device will function with other pieces of protective equipment.

Where to Buy PPE

Once you've determined the type of PPE that will keep your employees safe, you need to know where to purchase protective equipment. Mercedes Scientific is a laboratory and medical supply and equipment distributor with nearly 30 years of experience and options for a variety of markets.

Whether you're looking for a standard PPE kit, exam gowns, infection control supplies or various other products on your PPE list, reach out to us. We are proud to set ourselves apart with a customer-centric approach, and we look forward to helping you find the supplies you need at an affordable price.